Introduction:

In today’s fast-paced construction industry, businesses are constantly searching for ways to build smarter, faster, and more affordably. This is where Pre-Engineered Buildings (PEBs) come in—a revolutionary solution that’s transforming the way we think about construction.

Unlike traditional methods, PEBs are designed for **efficiency, cost savings, and scalability**. Whether you’re building a warehouse, industrial complex, or commercial space, PEB construction offers a flexible and cost-effective alternative** that delivers real value.

In this blog, we’ll explore how PEB structures can help you **optimize construction costs**, reduce timelines, and achieve top-notch results—all without breaking the bank.

What Makes PEB Construction Cost-Effective?

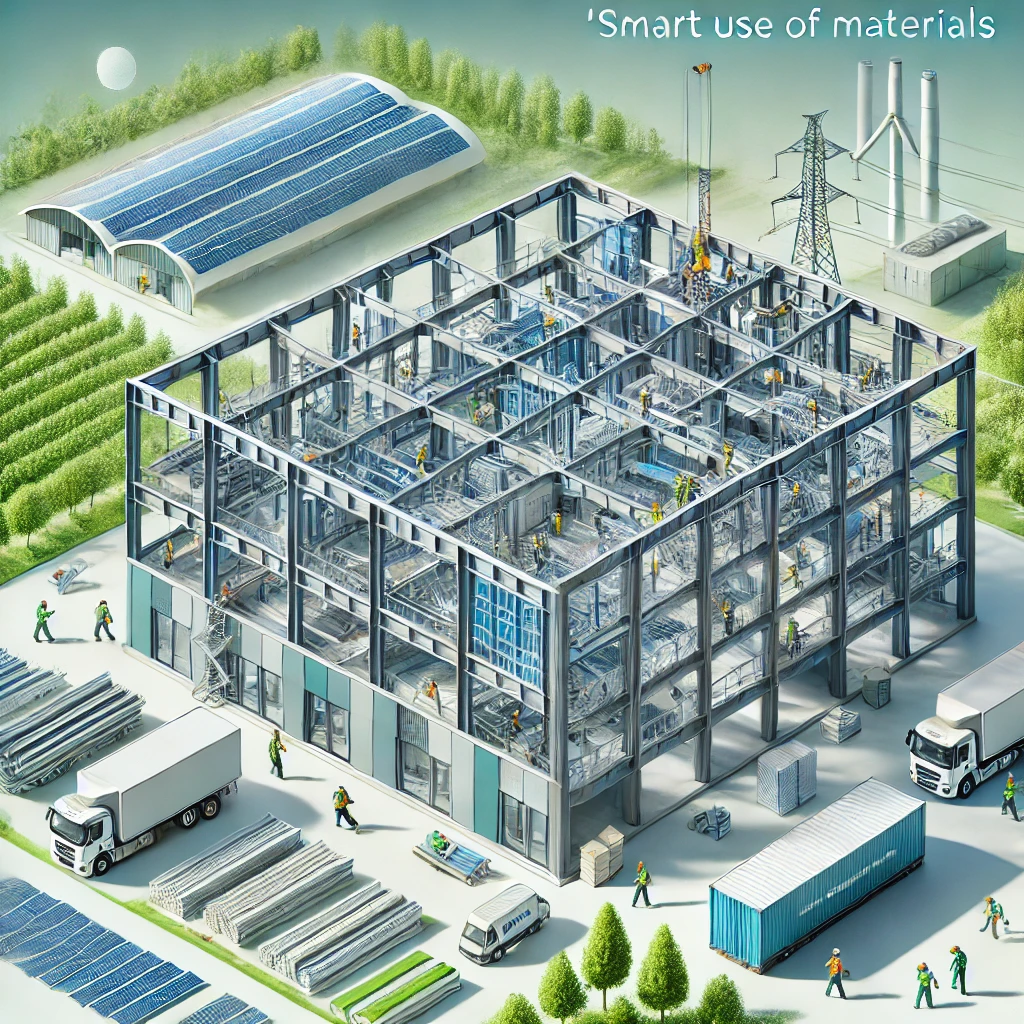

1. Smart Use of Materials:

PEBs are built with high-tensile steel, which is not only stronger but also lighter than traditional building materials. This reduces material wastage and ensures efficient construction.

2. Faster Construction = Lower Costs

Time is money, and PEBs save plenty of both. Since PEB components are pre-engineered and ready to assemble, construction timelines are drastically reduced. What might take months with traditional methods can often be completed in just weeks.

3. Flexibility and Scalability:

One of the standout features of PEBs is their adaptability. Need to expand or modify your structure in the future? No problem. PEBs make it easy to scale up or redesign without the hefty costs typically associated with traditional construction.

“PEB construction isn’t just about putting up steel structures—it’s about smart building, efficiency, and long-term value. Every beam, every joint, and every detail is designed with care, making construction faster, stronger, and more cost-effective. It’s about creating spaces that last, without wasting time or resources.”

Key Areas Where Costs Are Minimized:

PEB construction delivers significant savings across multiple areas. Here’s how:

1. Design and Engineering:

The design and engineering process for PEBs is standardized and pre-planned, eliminating the need to start from scratch for every project. This saves money on repeated consultations and revisions.

2. Transportation Costs:

PEB components are manufactured off-site and transported to the project location. Since the materials are lightweight and compactly packed, transportation costs are much lower compared to traditional materials like bricks and concrete.

3. Labor and Construction Time:

With PEBs, construction is faster and requires fewer workers. The streamlined assembly process reduces labor expenses and minimizes delays, keeping your project on track and within budget.

4. Maintenance Costs:

PEBs are built to last. The steel structures are durable, corrosion-resistant, and require minimal upkeep over the years. This translates to long-term savings compared to traditional buildings, where maintenance costs can quickly add up.

5. Energy Efficiency:

Many PEB structures are designed with energy-saving features like natural ventilation, proper insulation, and solar panel integration. These elements help reduce operational costs by cutting down on energy consumption for heating, cooling, and lighting.

Real-World Example: PEBs in Action:

Let’s take a look at how PEB construction delivered impressive cost savings for an e-commerce giant.

Case Study: Warehouse Construction

An e-commerce company needed a large warehouse to meet growing business demands. Traditional construction methods estimated a 10-month timeline and a hefty budget. Instead, they opted for PEB construction—and the results were remarkable

Construction Time: Completed in just 4 months, cutting the timeline by more than half.

Material Costs: Pre-engineered components reduced material wastage by 20%.

Energy Savings: Insulated roofing and walls lowered cooling costs by 30%.

The PEB design allowed for easy expansion when additional storage space was needed a year later.

By choosing PEB construction, the company saved over 30% on the total project cost and benefited from a faster, more flexible solution that could grow with their business.

The Future of Cost Optimization in PEB Construction

The world of PEB construction is evolving rapidly, with \new technologies and trends making it even more cost-efficient. Here’s what the future holds:

1. Integration of Smart Technologies

AI and IoT are set to revolutionize PEB design and construction. AI can optimize structural designs for maximum efficiency, while IoT sensors can monitor building performance, ensuring timely and cost-effective maintenance.

2. Modular Construction Advancements

Future innovations in modular construction will allow for even faster assembly, reducing costs further and minimizing disruption at construction sites.

3. Green and Sustainable PEBs

Sustainability is becoming a key focus in construction. Future PEB projects will incorporate eco-friendly materials and energy-efficient designs, helping businesses cut operational costs while reducing their environmental footprint.

Conclusion:

In a world where construction costs are constantly rising, PEB construction stands out as a smart, efficient, and cost-effective solution. By optimizing material use, speeding up construction timelines, and lowering maintenance and energy costs, PEBs offer businesses a way to save big without sacrificing quality.

As technologies like AI, modular construction, and sustainable designs** continue to shape the future, PEBs are becoming even more innovative and accessible. Whether you’re planning a warehouse, industrial facility, or commercial building, choosing PEB construction is not just a cost-saving decision—it’s an investment in smarter building practices.

If you’re ready to explore how PEB structures can transform your next project, we’d love to help. “Contact us today” to discover how we can deliver cost-efficient, high-quality solutions tailored to your needs.