The construction world is changing wonderfully into something great as we look to 2025. It is up to Pre-Engineered Buildings, through which building shall be expedited faster and more sustainably, besides loading new technologies within it. We at Pramila Projects feel happy to be part of this shift, especially as we work to interlink innovation with deep sense responsibilities. Our focus is building something that adds value to the lives of the people who actually use it and not just following what’s trendy.

Every structure we design has a purpose beyond the walls. For us, a building is space where ideas are born, communities connect, and progress is made. While we stay up on what’s new, we’re devoted to leading the practice set by higher standards. Our commitment? To make every project reflect not only industry standards but our commitment to quality, sustainability, and positive impact.

Here, we explore 10 game-changing trends in PEB construction, highlighting examples from leading PEB companies and how they are driving these transformative changes in the industry.

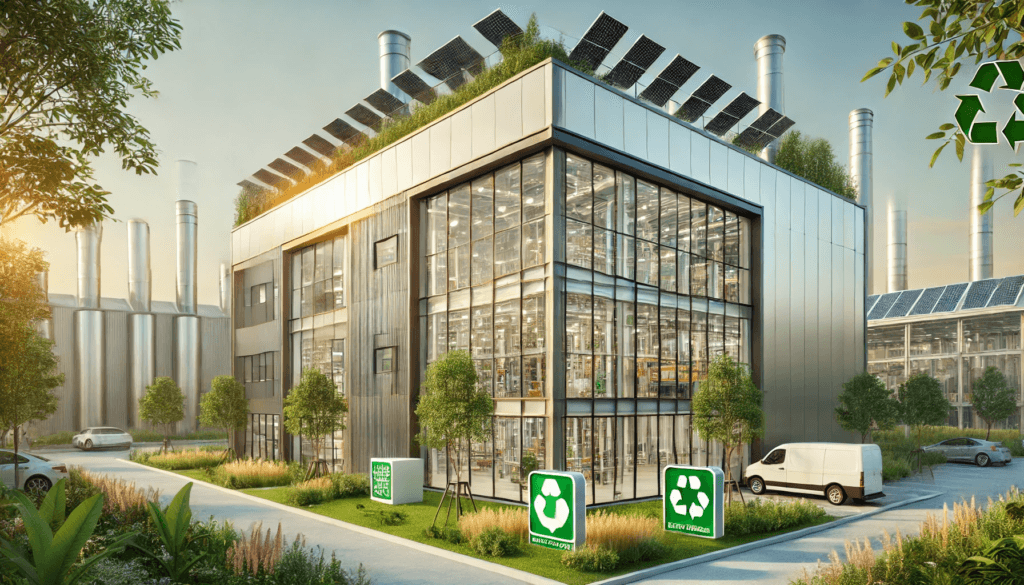

1. Green and Sustainable PEB Materials:

Pebsteel, a key player in the prefabricated steel industry, is actively involved in sustainable building practices. They use environmentally friendly materials like PebLeed™, which provides effective insulation while reflecting sunlight to reduce heat absorption. Additionally, Pebsteel applies green technology throughout their projects, including non-toxic paints and recyclable materials, ensuring a minimal carbon footprint and adherence to LEED (Leadership in Energy and Environmental Design) standards.

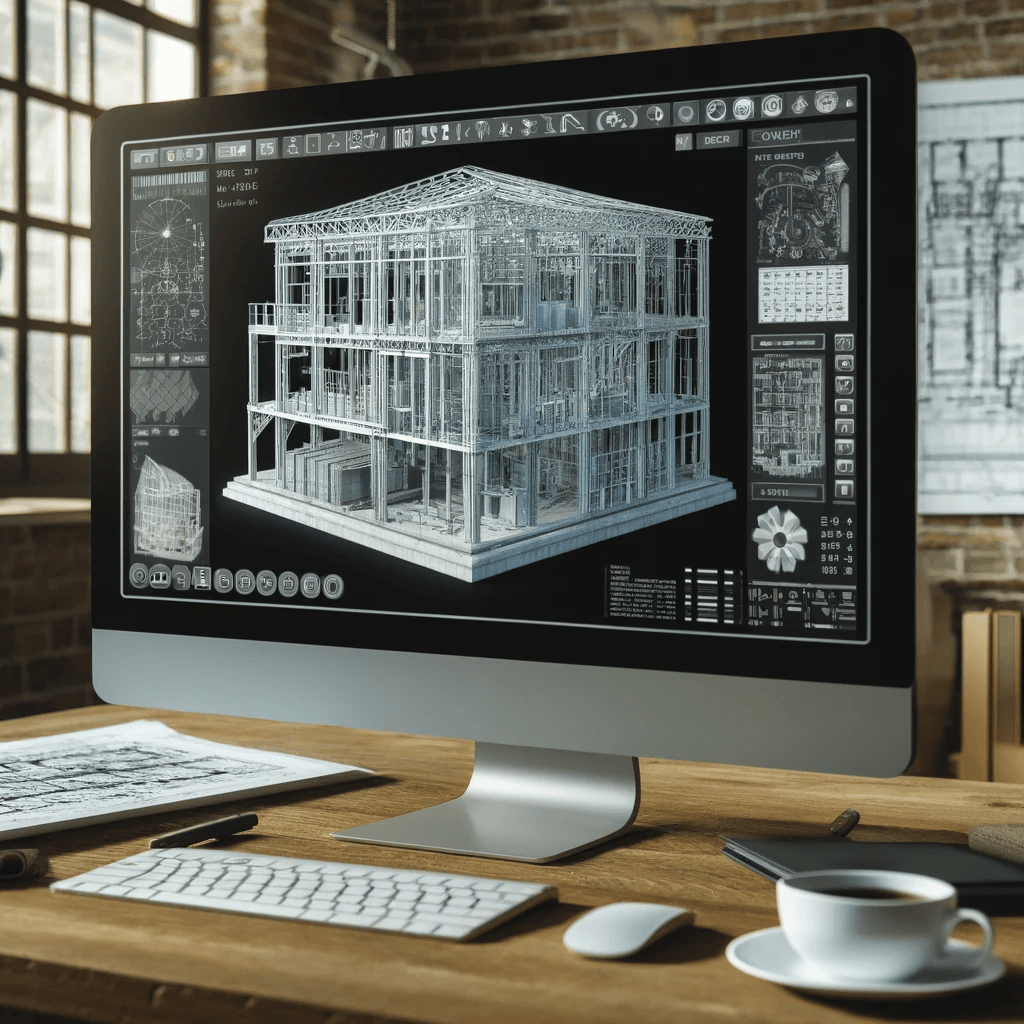

2. Advanced Design Software for Customization:

BlueScope Steel is another company leveraging advanced design tools in PEB construction. By integrating BIM (Building Information Modeling) and AI-powered software, they can create highly customized, efficient designs tailored to client needs. This approach speeds up the design and construction process, making project iterations faster and delivery timelines shorter.

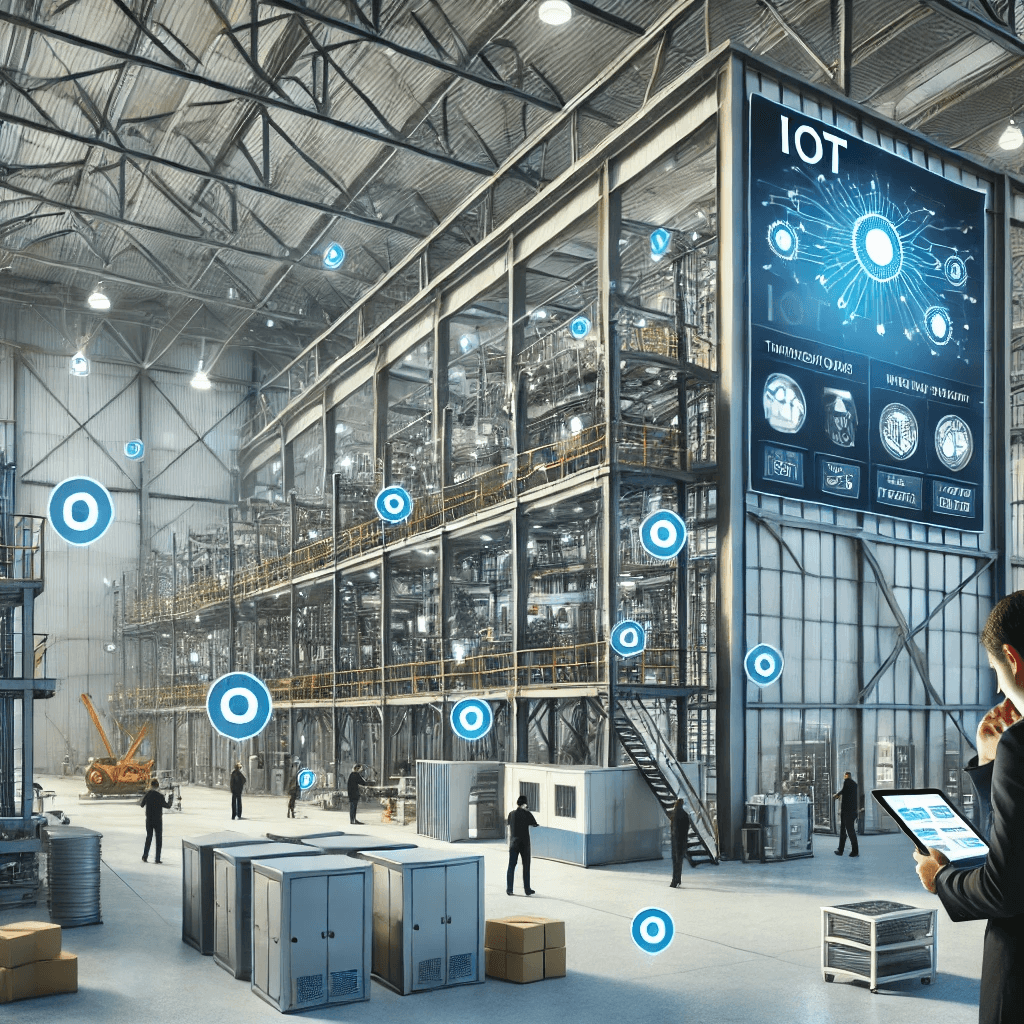

3. Smart PEB Buildings with IoT Integration:

Zamil Steel utilizes IoT in their pre-engineered buildings to create smart structures that adjust HVAC and lighting based on real-time data. Their adoption of IoT technology enables automated systems that enhance energy efficiency and reduce maintenance costs, demonstrating how IoT-driven automation can improve operational control in PEBs.

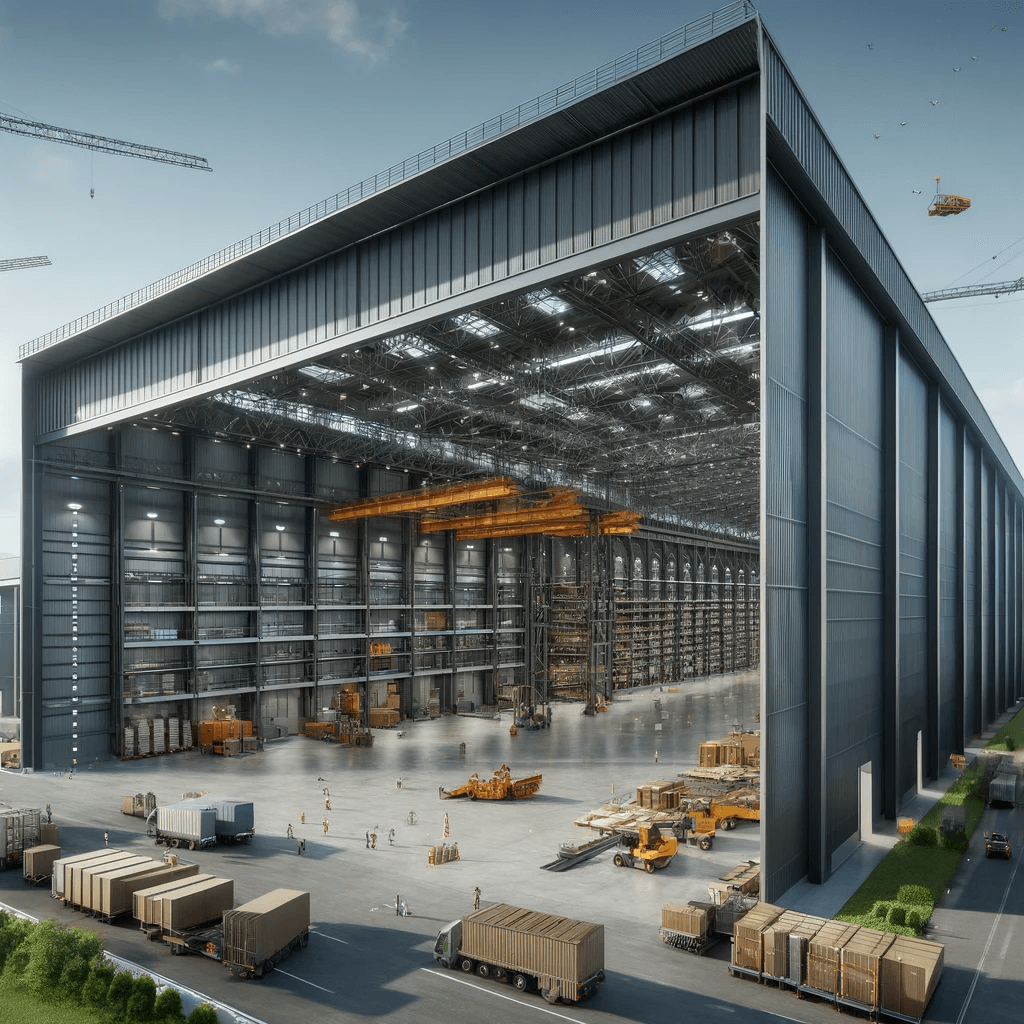

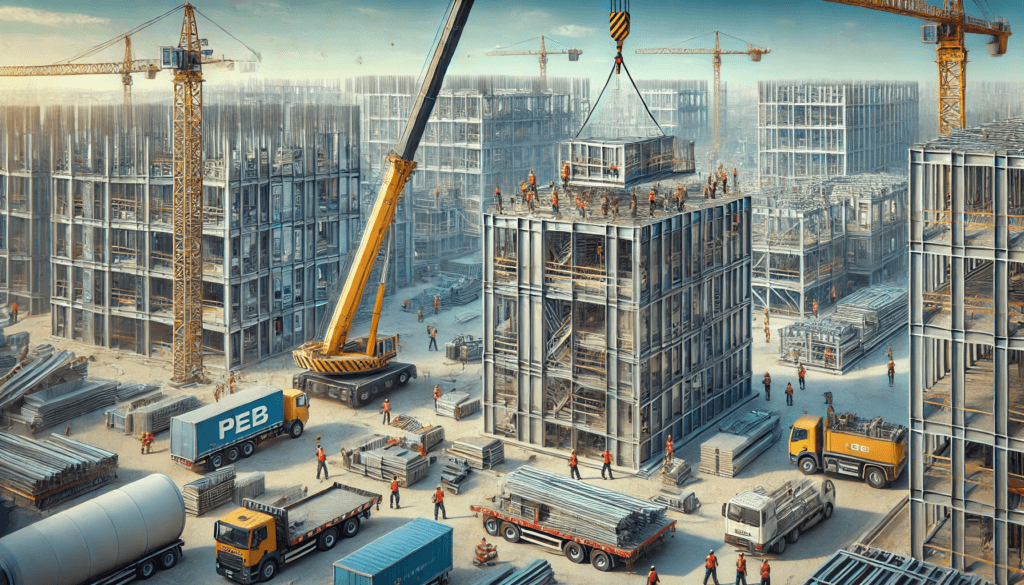

4. Modular PEB Construction for Faster Project Delivery:

Everest Industries in India has embraced modular PEB techniques, especially for industrial and commercial spaces. By fabricating parts offsite and assembling them onsite, Everest minimizes labor costs, shortens project timelines, and maintains quality standards—all key benefits that align with the demand for faster construction solutions.

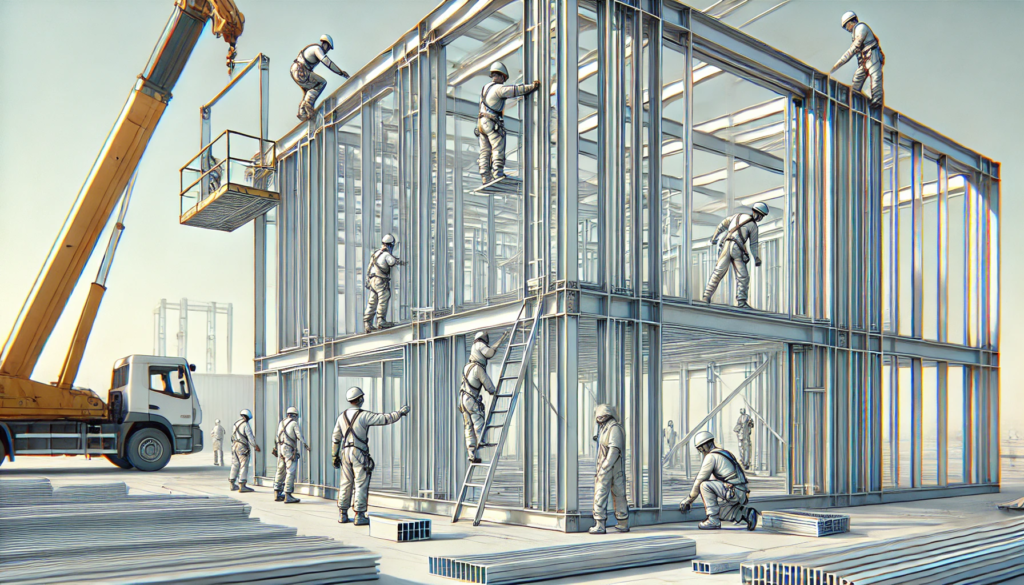

5. Lightweight Steel for Cost-Effective PEB Structures:

Several companies are actively advancing the use of lightweight steel in PEB construction to optimize cost and efficiency. For instance, Steel Frame Dynamics manufactures lightweight steel frames and modular solutions, which provide enhanced flexibility and are easier to transport and assemble, meeting the increasing demand for faster construction. Similarly, companies like Tata BlueScope Steel in India use lightweight, high-tensile steel in their PEB products, offering reduced material usage while maintaining structural integrity.

6. Solar Panel Integration:

As renewable energy integration becomes essential, ATCO has integrated solar panels into their PEB designs. Their facilities leverage solar energy to reduce overall power consumption, an example seen in some of their industrial and commercial PEBs, which actively harness solar power to reduce operational costs and environmental impact. Additionally, MBS (Modular Building Systems) includes solar roofing solutions in PEBs for sustainable energy use, supporting clients in adopting eco-friendly practices.

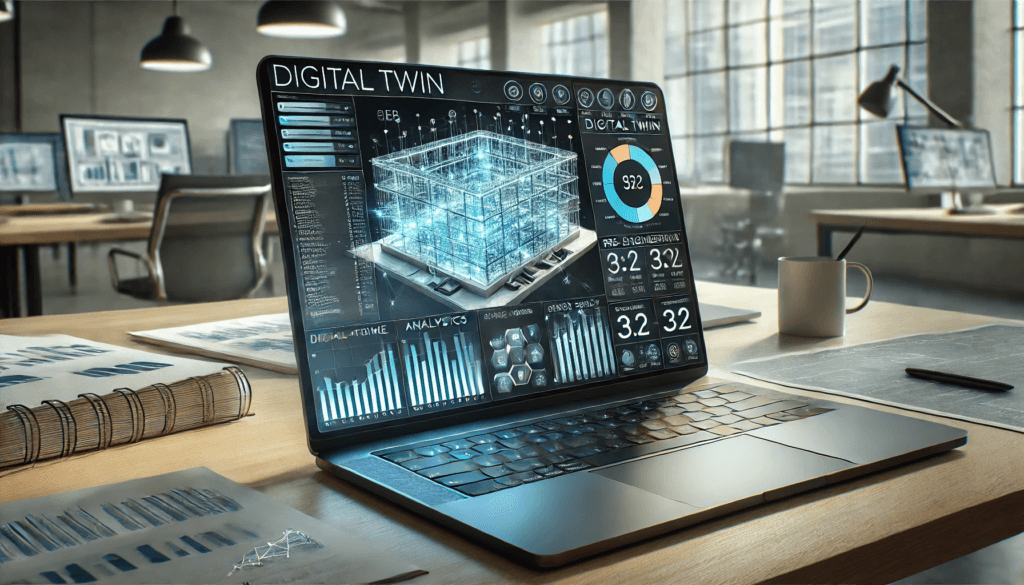

7. Digital Twin Technology:

Siemens and IBM are two leading companies that are adopting digital twin technology in building and facility management. These firms use digital twins to create a real-time digital replica of PEBs, helping operators analyze performance and detect issues early. This technology enhances monitoring and predictive maintenance, which is particularly valuable for large-scale industrial PEBs that require constant supervision.

8. Penetration of PEB into New Sectors (Education, Healthcare, etc.):

Companies like Tata Projects and Zamil Steel are leading the way in expanding PEB applications into sectors beyond industrial use, including education, healthcare, and commercial spaces. Tata Projects, for example, has worked on PEB structures for school buildings in India that provide rapid, cost-effective solutions for expanding educational infrastructure, especially in rural areas. Similarly, Zamil Steel has developed PEBs for healthcare facilities and retail spaces in the Middle East, where they enable quicker construction times and ensure compliance with local building codes for public safety.

9. Prefabrication for Quality Control:

Pinnacle LGS and Butler Manufacturing emphasize factory-controlled prefabrication, ensuring higher quality and reducing on-site labor. With stringent quality checks in their facilities, they provide clients with PEB components that meet exacting standards, thereby enhancing durability and reliability. The prefabrication process is especially valuable for projects in regions with strict building codes or limited skilled labor.

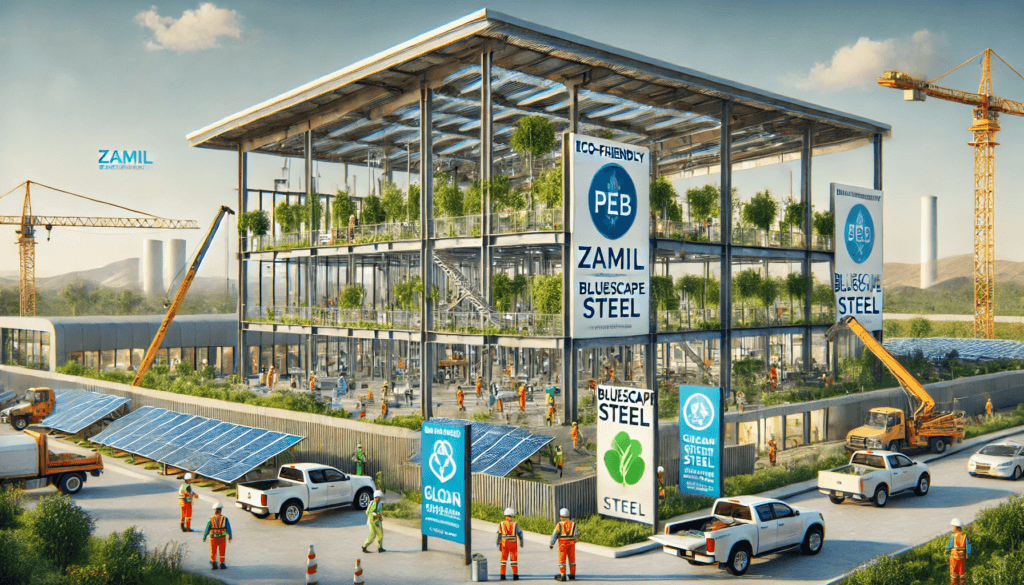

10. Regulatory Compliance Driving PEB Adoption:

In light of increased regulatory pressures for sustainable and efficient building solutions, Zamil Steel and Bluescope Steel are setting benchmarks with their PEB offerings that meet evolving environmental and safety standards. These companies provide PEB solutions that align with new sustainability regulations, making them attractive options for companies seeking compliance with stricter building codes across industries like healthcare, education, and commercial sectors.

Conclusion:

At Pramila Projects, we’re not just about constructing buildings—we’re about creating spaces that matter, spaces that stand the test of time and make a difference. Our goal is simple: to build for today with a clear focus on the needs of tomorrow. Whether it’s using smarter technology, sustainable materials, or innovative designs, we aim to deliver structures that are practical, durable, and kind to the environment.

We want to lead the way, not just follow. For us, it’s about raising the standards in the PEB industry while staying true to what matters most—quality, safety, and making a positive impact. Every project we take on is a step toward a greener, more connected future, and we’re proud to be part of this journey alongside our clients and communities.